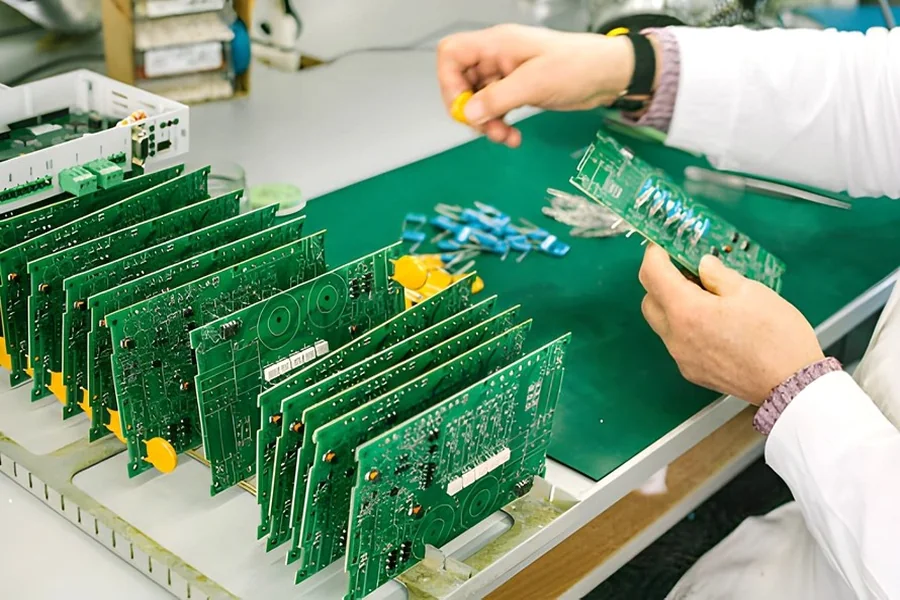

Low cost PCB assembly is one of the most practical and effective solutions for businesses looking to reduce production expenses without compromising quality. It focuses on optimizing material selection, simplifying design complexity, choosing the right manufacturing processes, and leveraging efficient assembly techniques. Whether you are developing consumer electronics, industrial products, IoT devices, or prototypes, cost-effective PCB assembly allows you to scale your product quickly and stay competitive in a fast-moving global market.

How Low Cost PCB Assembly Works

Achieving low-cost PCB assembly does not mean using cheap materials or sacrificing performance. Instead, it involves strategic planning at every stage—from design to manufacturing. The process begins with Design for Manufacturability (DFM) analysis, which ensures your board layout, components, and specifications can be produced efficiently. Streamlined assembly methods and optimized component sourcing also contribute to reducing overall costs.

The Role of PCB Design in Reducing Costs

A major portion of assembly cost is influenced by the PCB design itself. Using standard board sizes, minimizing layer count, selecting readily available components, and avoiding excessively fine-pitch parts can significantly reduce expenses. Engineers also optimize trace routing, component spacing, and thermal management to ensure the design is not only functional but economically feasible. When the design is optimized early on, the entire production process becomes smoother and cheaper.

Key Factors That Make Low Cost PCB Assembly Possible

Several elements directly affect pricing and efficiency:

- Component selection plays a major role. Choosing common and widely available components helps maintain lower procurement costs.

- Manufacturing process efficiency impacts overall budget. Automated SMT assembly is more cost-effective for medium to high-volume production.

- Board material such as FR4 is often ideal for balancing durability and cost.

- Panelization lowers waste and allows multiple boards to be processed simultaneously.

- Testing levels can be adjusted depending on product purpose, which also affects pricing.

These factors combined help manufacturers achieve affordable yet reliable PCB assembly suitable for both prototypes and mass production.

Benefits of Choosing Low Cost PCB Assembly Services

Businesses choose low cost PCB assembly because it offers a strong balance between price and performance. One major benefit is the ability to scale quickly. When production costs are controlled, brands can respond faster to market demand and launch products at competitive prices. Low cost assembly also enables rapid prototyping, allowing engineers to test multiple versions without overspending. For startups and small electronics companies, this affordability creates opportunities to innovate without high financial risk.

Quality Assurance in Low Cost PCB Assembly

Even when focusing on cost efficiency, quality must remain a priority. Advanced inspection technologies such as AOI, X-ray, and functional testing help ensure every board meets performance and safety standards. Many manufacturers follow IPC guidelines, use high-quality solder materials, and implement controlled processes during reflow and wave soldering. With proper quality control, low cost PCB assembly can achieve performance comparable to higher-priced alternatives.

Applications of Low Cost PCB Assembly

Low cost PCB assembly is widely used in various industries where affordability and functionality must go hand in hand. In consumer electronics, it helps reduce overall product pricing. IoT companies rely heavily on cost-effective assembly to produce sensors, smart home devices, and wearables. Industrial automation, LED products, toys, and communication modules also benefit from low cost manufacturing that maintains reliable performance. For educational and prototyping purposes, this cost advantage allows teams to experiment freely.

How to Optimize Your Project for Low Cost PCB Assembly

To maximize savings, it is important to collaborate with your manufacturing partner early in the design phase. Reviewing BOM, simplifying the PCB structure, removing unnecessary components, and ensuring proper footprints make the board easier to assemble. Choosing manufacturers with strong supply chain networks also ensures cheaper and faster component sourcing. Batch ordering and long-term manufacturing plans can further reduce costs.

Why Partnering with Experienced Providers Matters

Working with the right assembly partner can significantly improve cost efficiency. Experienced providers offer engineering guidance, DFM analysis, and reliable material sourcing. They understand production constraints and suggest practical improvements to help you stay within budget while maintaining high performance. They can also meet tight deadlines, handle different order volumes, and provide consistent quality across multiple production runs.

Final Thoughts

Low cost PCB assembly gives businesses the opportunity to create reliable electronics while staying within budget. It combines smart design practices, efficient production methods, and optimized sourcing strategies. When you are ready to start your next electronics project, consider working with a professional printed circuit board assembler that can help you achieve affordable, high-quality, and scalable production tailored to your needs.